Casing head is generally cast from steel and usually includes two main parts: outer jacket and inner lining. The outer jacket is the outermost layer inserted into the next casing, and the inner liner is the inner layer inserted into the next casing. The casing head also includes some other connecting parts, such as threaded rings and sealing rings.The connectors produced by our company are mainly used in the petroleum industry. Raw materials are purchased from round steel with recognized quality at home and abroad.

지금 연락

The manufacturing process of the support shaft roughly includes the following steps:1. Material preparation: Select suitable raw materials for processing, usually steel or cast iron.2. Processing and manufacturing: According to the design drawings of the support shaft, the raw materials are processed and manufactured by using lathes, milling machines, drilling machines and other machines. The machining process mainly includes turning, drilling, tapping, grinding, etc., so as to make various parts of the supporting shaft.3.

지금 연락

Our Baohua company is able to independently design and develop the die, which makes the torque arm forge in one shape, saves material greatly and improves the stability of the product. Moreover, Baohua has the finishing ability, which can cover many processes such as forging, machining, heat treatment, finishing and so on. Finally, the finished product can be delivered. And we can deliver according to customer needs in different delivery states. The torque arm is a suspension component mounted on the rear drive axle of rear wheel drive vehicles.

지금 연락

Our company independently designs dies and forges according to product specifications. Material types and weights can be made according to customer requirements. Our company also has rough machining, heat treatment and fine machining, which can be delivered according to the requirements of customers in different delivery states. About finish machining, we have more than 80 sets of different processing machinery and equipment, as well as ZEISS three-coordinate, Japanese small plate profilometer, gear tester, OmeGA tool counter and other inspection and testing equipment.

지금 연락

Our Baohua company has mold design engineers who can provide drawings according to customersIndependently designed and developed the mold, making the fixed shaft locking sleeve integrally forged, greatly saving materials, and improving the stability of the product. In addition, our company has the ability of finishing, which can cover multiple integrated processes such as forging, machining, heat treatment and finishing, and can finally achieve the delivery of finished products.

지금 연락

The output tools shaft synthetic by means of us can be product of forty five#, 40cr, 30crmo, 35crmo, 42crmo, 18crnimo7-6 and other substances according to consumer requirements. it can be forged on different forging device gadgets in step with one-of-a-kind weights. the forging product weight can attain 6kg-500kg. the forging method wishes to be finished by means of heating, pre-forging, forming and trimming.According to the different shapes of axes, shafts can be divided into crankshaft and straight shaft.

지금 연락

Our products at Bauer are based on manufacturer-provided flexibility in shape, size and material, lower volume requirements and near-finished shapes that save on final processing costs. And all our forgings can go through hot die forging, rough machining, heat treatment and other processes, and the forgings can be finished to reach the final assembly condition. Our company has API certificate and SQ1 certificate and has many years of experience in petroleum product processing.We support mass production, and the quotation of products can be communicated according to the market price.

지금 연락

These hollow shaft may be crafted from ferrous and non-ferrous metals which include carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum and device steelBAOHUA produces solid gear, ring gear shapes for single, double and different close to internet shapes for completing into numerous unique shapes.OUR FORGED GEAR SHAPES & ALLOYSHelical GearsBevel GearsHypoid GearsWorm GearsSpiroid GearsTorsoing GearsBAOHUA uses a seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requirements and near-finished shapes t

지금 연락

According to your needness, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.According to the forming mechanism, forging can be divided into free forging, die forging, ring rolling and special forging.1. Free forging.

지금 연락

Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing. And has ISO 9001, API 20b and API Q1 certificates.The forging equipment of our Baohua company mainly includes: five tons and three tons of free forging hammers, 2500 tons, 1000 tons and 600 tons of friction presses, six large splint hammers and various types of air hammers, and 1000 tons of multi-directional die forging presses.

지금 연락

The inner gear ring produced by way of our baohua company is in particular used within the oil enterprise and gadget add-ons of construction equipment. forging the dimensions of the internal equipment ring in line with the requirements of clients for using spherical metallic in product materials. batch purchase can open molds for specialised deliver and finishing production. At present, our organization has more than one hundred cnc lathes and finishing system.

지금 연락

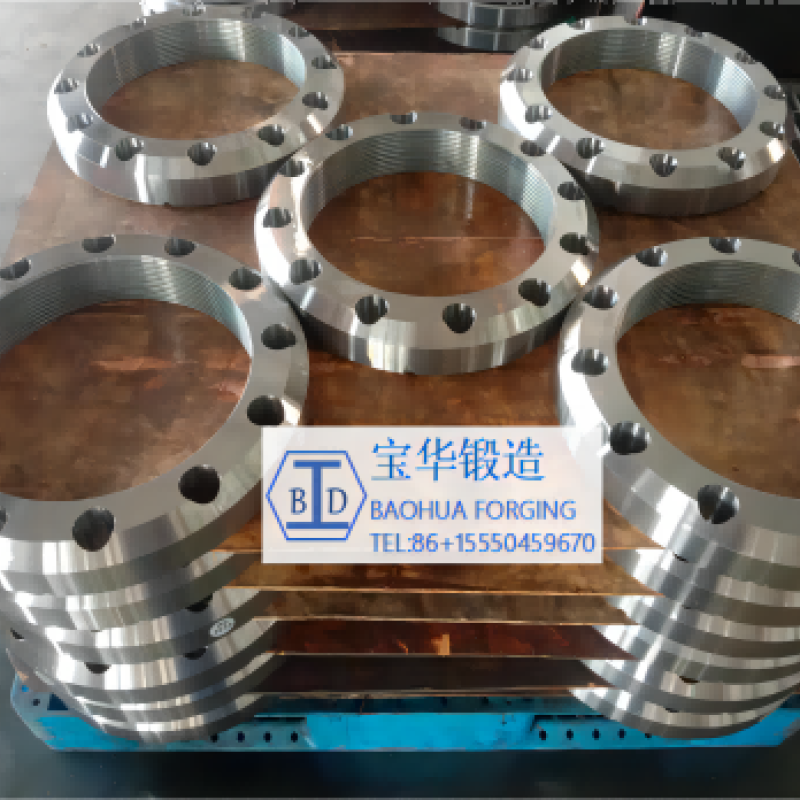

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment, and is used for the connection between two equipment, such as reducing pipe flanges.

지금 연락

According to consumer requirements, we are able to make scrapers of numerous substances along with 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc. According to exclusive weights, we are able to forge on different forging system units. Our organization independently designs and manufactures molds , will maximize the financial savings of product substances and decrease forging weight, with the intention to attain price financial savings for customers.

지금 연락

The internal tools ring produced by using our baohua organization is specifically used within the oil enterprise and gadget accessories of creation equipment. forging the scale of the internal gear ring according to the necessities of clients for the use of spherical metal in product materials.

지금 연락

Forging gear and ring gear blank processBAOHUA makes use of a unbroken rolled ring method to offer cast tools producers with shape, length and material flexibility, decrease volume necessities and near-completed shapes to store on very last machining costs. Higher nice and accelerated electricity and put on in cast tools blanks is done from contoured grain flow, decreased grain length and thermal processing that improves mechanical residences and metallurgical soundness from the open die forging manner.

지금 연락

The purpose of the utility model is to overcome the above shortcomings of the prior art, propose a tooling for gear end caps, which can realize the positioning and fixation of various types of gear end caps.In order to achieve the above purposes, the utility model adopts the following technical solutions:The utility model relates to a tool for a gear end cover, which comprises a support plate for supporting the gear end cover; The gear end cover comprises a circular main body, a plurality of positioning holes on the main body, and a plurality of bolt holes on the main body; The positioning hol

지금 연락

With regard to inner ring end cap, we can make many kinds of materials according to customer requirements, such as 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc. Our company independently develops ring forging process, which can greatly improve forging efficiency and reduce blanking weight, and ultimately achieve the purpose of cost saving. According to the weight, forging is carried out on different forging equipment units. The weight of forged products can reach 6kg-2000kg. The forging process needs to be completed by heating, pre-forging and forming.

지금 연락

The internal gear ring is a kind of circular gear, the teeth of which are inward. It is usually used to transmit mechanical systems such as differential, reducer, steering gear, planetary gear box, etc.

지금 연락

Gear is a commonly used mechanical transmission element, which is used to transmit torque and rotary motion. It consists of one or more tooth tips, usually in the shape of a disk or a cylinder. The main function of gear is to realize the transmission of speed and torque, and at the same time, it can also change the steering and transmission direction.NAMEGEARMATERIAL18CrNiM07-6HARDNESS140-240INNER DIAMETER121OUTSIDE DIAMETER299.48Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

지금 연락

The internal gear ring produced by our Baohua Company is mainly used in the oil industry and equipment accessories of construction machinery. Forging the size of the internal gear ring according to the requirements of customers for using round steel in product materials.

지금 연락

Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing. And has ISO 9001, API 20b and API Q1 certificates.The production of oil union is mainly used in the accessories of oilfield wellhead equipment.

지금 연락

The production of union products is based on the drawings provided by the customer, independently designing the mold, and adopting the integrated forging of double mold cavities. While ensuring the accuracy, it greatly saves materials and improves the stability of the products. In addition, our Baohua company has the ability of finishing, which can cover multiple integrated processes such as forging, machining, heat treatment, finishing, and finally can achieve the delivery of finished products. The cylinder head is a box shaped part with complex structure.

지금 연락

Our company uses the seamless rolling ring process, which makes the product more stable and can greatly reduce the weight of blanking and save cost. Forged flanges can be made of a wide range of materials including but not limited to 4140, 4130, 35CrMo, 20CrMnMO and can be forged and machined in a wide range of sizes and sizes ranging from 200mm to 3000mm in diameter.All of our forgings can be forged by hot-die forging, rough working, heat treatment and other processes, increasing the forging ratio and performance stability.

지금 연락

Our company is able to design dies independently and forge according to product specifications. Material type and weight can be made according to customer requirements. Our company can design the die according to the drawings provided by customers, thus realizing the precision forging, which makes the material utilization more than 90%, thus greatly saving the cost.In addition, our company also has rough machining, heat treatment and finish machining, a complete line process, and delivery according to customer requirements of different delivery status.

지금 연락