Our company has ISO9001, API, SQ and different certificate, more than 80 units of processing machinery and equipment, in addition to zeiss cmm, japanese small plate profiler, gear detector, ω mega tool placing device and other inspection and trying out system.For the production of Crusher Hammer, our organisation can independently design the mould consistent with the drawings furnished by means of the customer, and use one-of-a-kind materials consistent with the product specifications, through a sequence of techniques consisting of hard machining, heat remedy, and completing for mass productio

지금 연락

For the production of Crusher Long Hammer with merchandise, our company can independently design the mould consistent with the drawings supplied by the consumer, and use one-of-a-type materials regular with the product specifications, thru a chain of techniques inclusive of tough machining, warmth remedy, and completing for mass production. we also can deliver in line with the purchaser's necessities of various shipping status.

지금 연락

For the manufacturing of Crusher Long Hammer products, our agency is capable of independently design dies and forge according to product specifications. cloth type and weight can also be produced in line with client requirements.

지금 연락

Our company is able to design the die according to the drawing according to the customer's requirements and achieve precision die forging, so that the utilization rate of rough processing hammer handle materials can reach more than 90%, which greatly saves costs. Our company can deliver according to the needs of customers with different delivery status.

지금 연락

Our Baohua Company is a state-owned to private enterprise. The family business has a history of more than 60 years, from the initial forging iron pieces to the current rough processing, heat treatment and finishing of forgings. Instruments and equipment also closely follow the requirements of modern product production. At present, there are more than 80 processing equipment, as well as ZEISS CMM, Japanese small board profiler, gear detector, Ω MEGA tool setting instrument and other inspection and detection equipment.

지금 연락

Our baohua business enterprise is a kingdom-owned to non-public organization. the own family enterprise has a history of greater than 60 years, from the initial forging iron portions to the current hard processing, heat remedy and finishing of forgings. gadgets and device also intently comply with the requirements of present day product production. at present, there are extra than 80 processing gadget, in addition to zeiss cmm, japanese small board profiler, gear detector, ω mega tool setting tool and different inspection and detection gadget.

지금 연락

We have API 20B and other certificates for many years, and we are very skilled in producing related products such as bar heads.This product is used on construction machinery or petroleum equipment. Use the corresponding type of die forging hammer to forge in one piece, with high efficiency and low cost. After repeated pre-forging by heating, the forging ratio is high after die forging, and the durability is good, which is suitable for the key parts of the equipment.

지금 연락

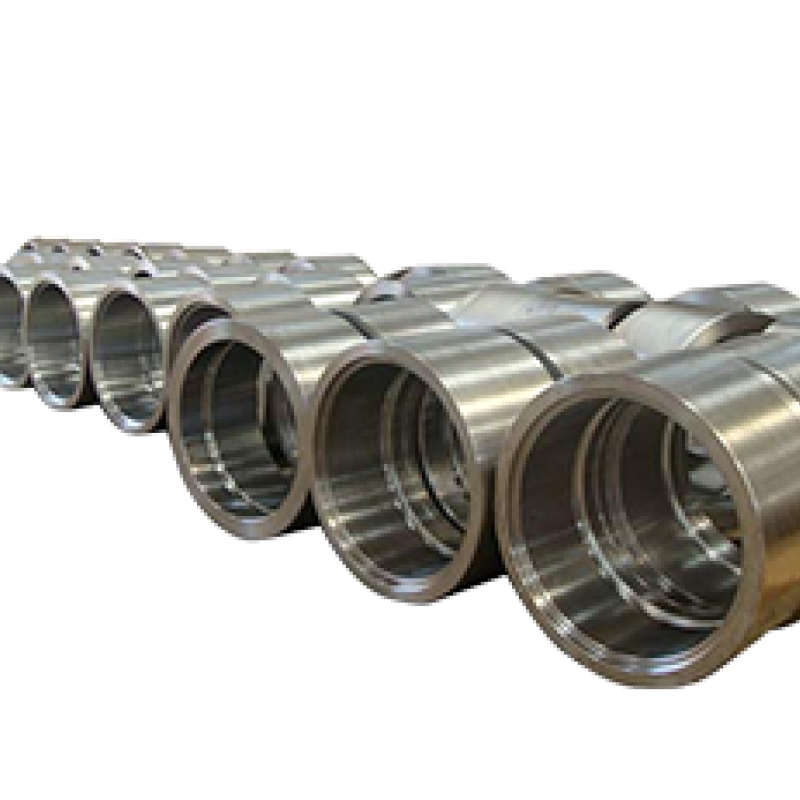

Our company has ISO-9001 certificate, and the production of supporting shaft is integrally forged with a corresponding model of die forging hammer, with high efficiency and low cost. And various types of materials can be used, such as 42CrMo, 45#, 35CrMo, 4140, 4130, etc. After repeated heating pre-forging and die forging, the forging ratio is high and the durability is good. It is suitable for fitting installation of engineering machinery and wind power industry equipment.

지금 연락

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-5000kg, Forging needs to be completed through heating, pre-forging, forming and other processes.Stainless steel forgings refer to the articles in which stainless steel materials are pressed to shape the required shape or suitable compression force through plastic deformation.This force is typically achieved by using a hammer or pressure.

지금 연락

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

지금 연락

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

지금 연락

The working medium used by the hydraulic press not only transfers the pressure, but also ensures that the working parts of the machine work sensitively, reliably, with long service life and less leakage. The basic requirements for working medium of hydraulic press are: ① proper fluidity and low compressibility to improve transmission efficiency; ② Able to prevent corrosion; ③ Good lubrication performance; ④ Easy to seal; ⑤ Stable performance, no deterioration after long-term operation.

지금 연락

The valve is forged in one piece, saving materials and reducing costs.Introduction: According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units.

지금 연락

After heating and repeated forging, it can also be modulated heat treatment and finishing according to customer requirements, so after repeated forging, the forging ratio is high, the durability is good, and it is suitable for key accessories of equipment.

지금 연락

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.The design of forged steel and the abrasive tools for its production require initial costs.

지금 연락

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg. Heating, pre-forging, forming, trimming and other processes are completed.Coupling refers to a device that connects two shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions.

지금 연락

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.Flange is also called flange plate or flange. Flanges are the parts that connect pipes to each other and are connected to pipe ends. There are holes on the flange, and the bolts make the two flanges tightly connected.

지금 연락

If you need to order bucket teeth, you can choose us. Our company has many years of forging experience. Our company can independently design and process forging dies according to drawings, and will try our best to save forging materials. The weight of the forged product can reach 6kg-50kg, and the forging needs to be completed through the processes of heating, pre-forging, forming and trimming. Various materials including 42CrMo, 4140, 4130, 40Cr, 20CrMnMo, 18CrNiMo7-6, 410SS can be forged.1.

지금 연락

Our company can independently design and process forging dies according to the drawings, and will try our best to save forging materials. The weight of the forged product can reach 6kg-500kg, and the forging needs to be completed through heating, pre-forging, forming, trimming and other processes.

지금 연락

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units, and the weight of the forged products can reach 6kg-5000kg, forging needs to be completed through heating, pre-forging, forming and other processes.Forging is a processing method that uses forging machinery to exert pressure on metal blank to make it produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes.

지금 연락

Our company employs a new seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requirements and near-finish shapes to save on final tooling costs. All of our forgings can go through hot die forging, rough machining, heat treatment and other processes, and the forgings can be finished to reach the final assembly condition.

지금 연락

According to consumer requirements, we are able to make scrapers of numerous substances along with 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc. According to exclusive weights, we are able to forge on different forging system units. Our organization independently designs and manufactures molds , will maximize the financial savings of product substances and decrease forging weight, with the intention to attain price financial savings for customers.

지금 연락

The company adopts seamless rolling ring technology, which makes the product performance more stable, weight greatly reduced and cost greatly reduced. Forged threaded flanges can be made of a variety of materials, including but not limited to 4140, 4130, 35CrMo, 20CrMnMO, and can be forged and processed into various sizes and diameters ranging from 200mm to 3000mm. Customers in any industry using threaded flanges can request quotations for any number of forged threaded flanges, from one prototype at a time, small batch to mass production.

지금 연락

The joint seats produced by our company are mainly used in wind power generation industry. Raw materials are purchased from hot rolled round steel or steel ingots recognized at home and abroad. We can carry out hot forging according to customers' requirements, and meet the requirements of ultrasonic flaw detection (UT). Forging can improve product performance and save costs.

지금 연락